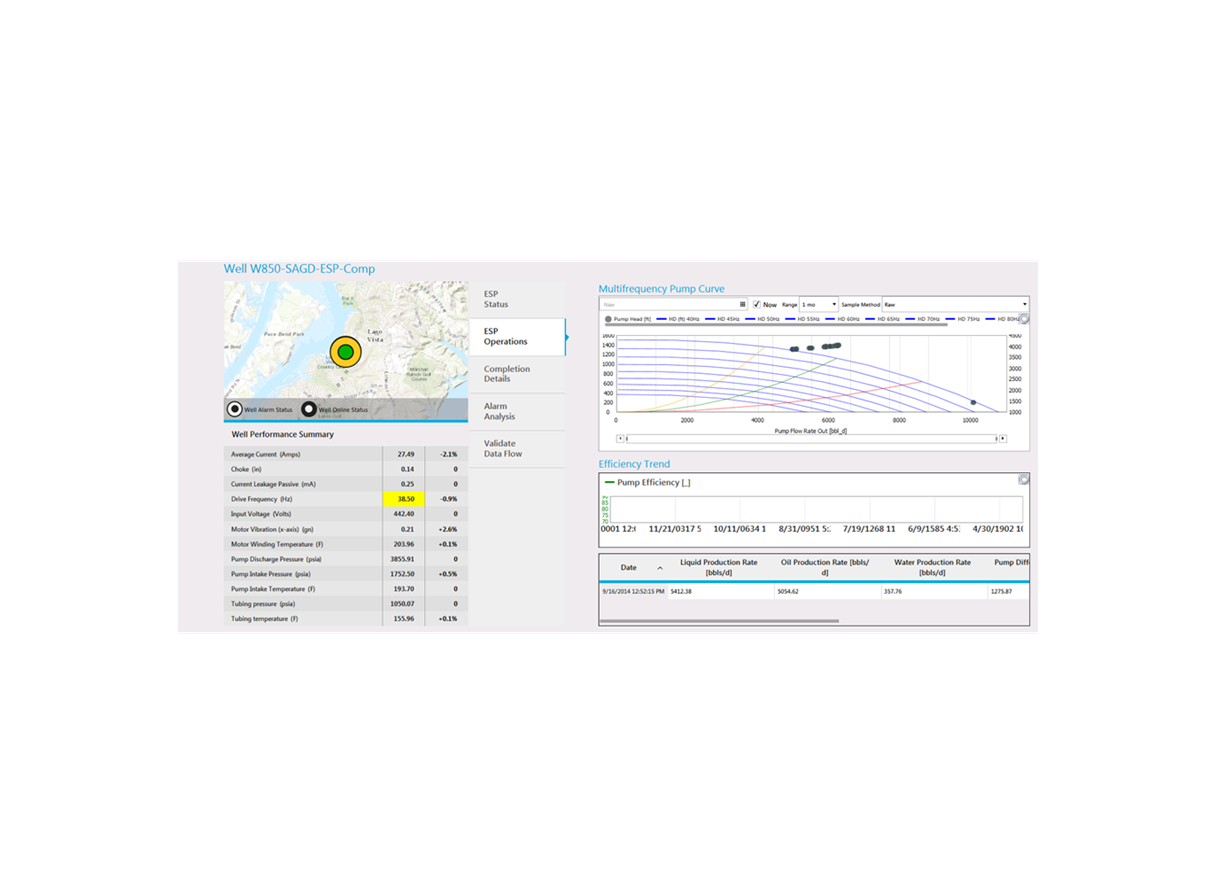

The ESP surveillance operations solution provides real-time monitoring and surveillance for multiple ESP installations via an intuitive graphical display. The solution improves awareness of field ESP operational parameters and helps surveillance engineers focus their initial efforts on problematic wells. It also provides a highly collaborative environment to improve artificial lift management efficiency, allowing more time for enhanced reporting and production optimization.

ESP status at a glance

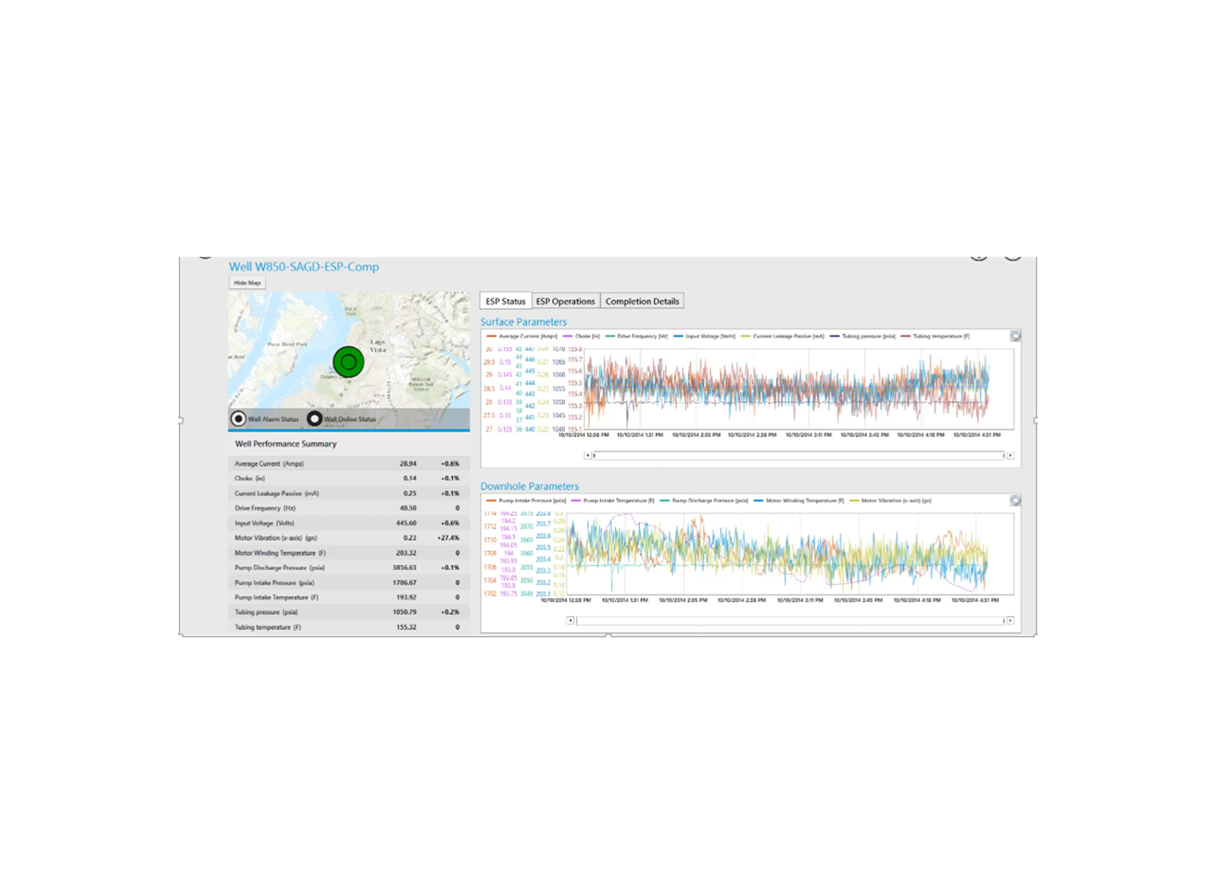

ESP surveillance incorporates ESRI GIS mapping technology to give users a comprehensive, bird’s eye view of pump performance in a field, complete with geographical context. It is possible to visualize a specific pump’s status and access its associated metric alarms—all with a simple click. The solution provides access to high-frequency data and advanced workflows based on a preliminary diagnostic in which critical pump-surveillance events and the potential for optimization can be addressed.

KPIs to enable decision making

The time-based ESP surveillance interface enables the effective management of any type of artificial lift equipment. New items can be created in the database inventory and followed over their entire field life using the intuitive links interface. The system supports any KPI reporting requirements—such as pump run time between failures and other inventory indicators—and makes them immediately available.

Pump diagnostics and optimization

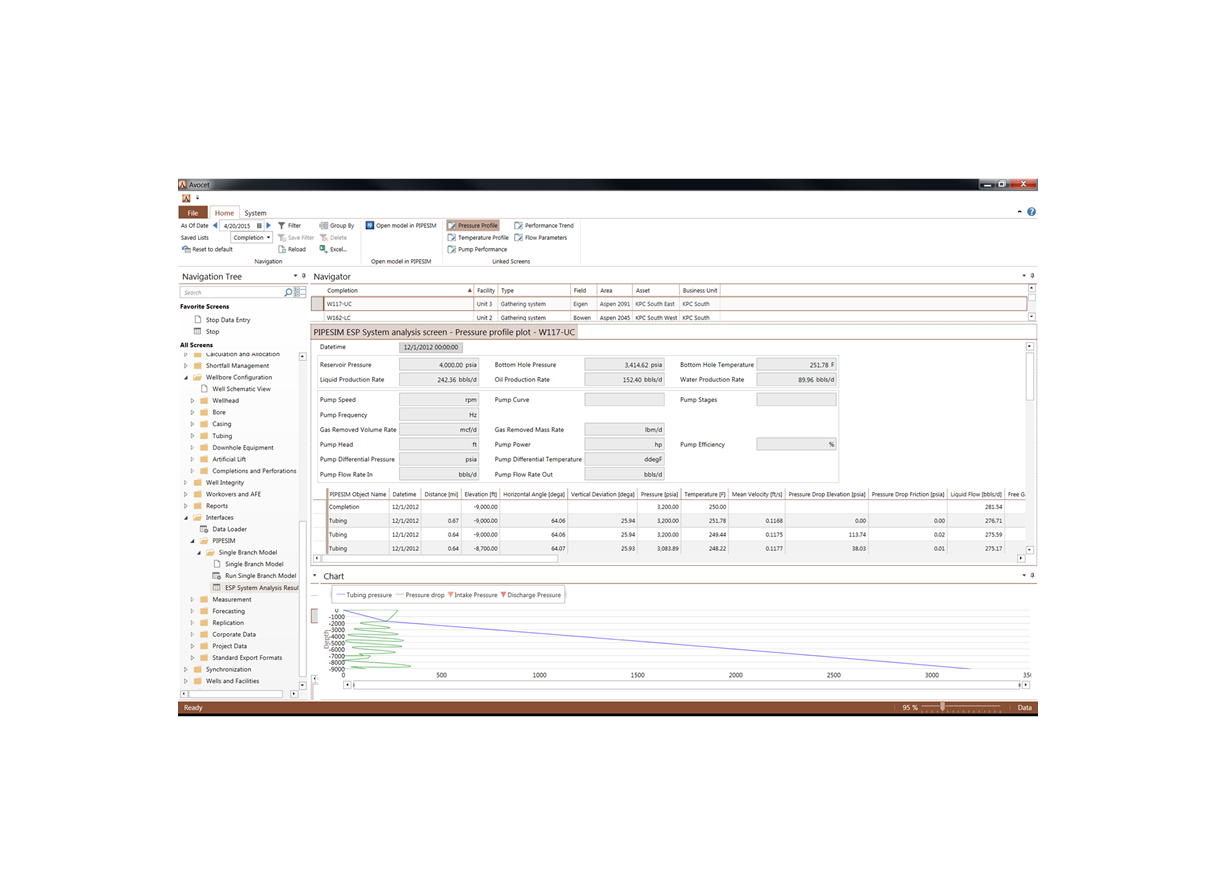

The ESP surveillance solution enables teams to work collaboratively in a single environment with standardized workflows. Integration with the PIPESIM steady-state multiphase flow simulator enhances the performance of pump diagnostics, allowing the detection of any change outside of predefined operation boundaries. For any point in time, the model can be run on demand for further advanced pump optimization.

Applications

- High-frequency ESP monitoring and surveillance.

- Model-based nodal analysis for ESP diagnostics and optimization.

- ESP flow rate estimation and well performance monitoring.

Benefits

- Maximum uptime through continuous ESP surveillance.

- Field overview of current well and ESP operational status with interactive visualization.

- Avoidance of deferred production by responding faster to well events.

- Improved pump run life.

- Optimized well performance in a collaborative environment.

- Available for ready deployment with online production data management systems.

Features

- Integration with the Avocet platform.

- Dynamic ESRI-enabled GIS mapping.

- Multilevel alarm configuration and intelligent filtering.

- Real-time and historical data visualization.

- Tracking and reporting of lifting equipment inventories.

- Single and multistage pump manufacturers’ curves display.

- Time-based system for inventory tracking and KPI determination.

- Compatibility with various data historians.

- Custom calculations and reporting.