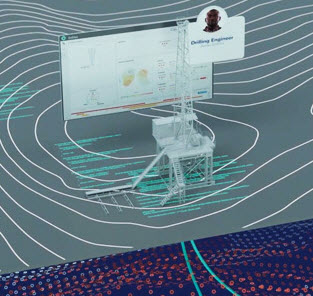

Dragon Oil using AI to Enhance Planning and Performance in a Mature Offshore Field

With cloud-computing technology and AI solutions, Schlumberger enabled Dragon Oil to optimize modeling and field-development plan (FDP) workflows in a mature offshore field.

The asset

A mature oilfield discovered in 1967, characterized by thick sedimentary deposits and complex tectonic structure. The field contains almost all the fluid types from black oil to volatile oil and gas condensate. The reservoir comprises of complex heterogeneous, unconsolidated and consolidated sandstone, where permeability varies from few milli-Darcy to multi-Darcy level as reservoir depth deepens. A highly complex geological structure—due to its “flower-shaped” faulting system—has led to unfavorable water movement and arduous well placement in heterogeneous layers.

The challenge

In total, nine distinct reservoirs were included in the program of work. The ability to model the reservoirs with their complexity—considering the range of uncertainty and running simulations in an acceptable timeframe—was critical to understand the subsurface, evaluate risk and optimize the FDP. Dynamic models only existed for some of the reservoirs in scope, composed through time-consuming manual workflows and long simulations that ran into days using existing on-premises infrastructure. No dynamic modelling was available for the deeper, more complex reservoirs, and Dragon Oil was unable to optimize the infill drilling locations and the waterflood and gas-injection plan.

The solution

Leveraging the potential of cloud computing and AI capability, Schlumberger deployed the Agile Reservoir Modeling solution enriched with RE Data Science & Innovation through the DELFI cognitive E&P environment, to improve and accelerate the different modeling steps, find new opportunities and optimize FDP workflows at scale.

“Thanks to Schlumberger’s team, DELFI, and AI/machine-learning solutions, we were able to successfully produce optimized field development plan for all of our assets, both faster and with higher confidence,” said Ali Al Jarwan, CEO, Dragon Oil (Holdings) Ltd.

The results

-

Simulation time cut by four: 3,860 CPU hours was performed in four to five months- the equivalent to one and a half years of 24/7 simulation using Dragon Oil's current set-up.

-

In a couple of weeks, optimized FDPs were produced for six complex reservoirs, using minimal resources. With Dragon Oil's existing infrastructure, this would have taken several months to complete.

-

Fully calibrated dynamic models were made possible for all reservoirs, irrespective of their complexity. Simulation runtimes went from days to hours in the cloud.

-

Infill-drilling locations for all reservoirs could be optimized and prioritized.

-

Screening of waterflood and gas-injection programs were performed for shallow reservoirs.

-

Automated workflows were employed to generate new opportunities and insights.

-

The oil-recovery factor was increased.

-

Workforce productivity was improved.