AI and Automation Accelerates Candidate Selection for Well Intervention up to 90%, Offshore Indonesia

Today’s oil and gas companies operate under tight margins, so a major goal is to increase production from existing assets as efficiently and economically as possible. A strategic well intervention program can help achieve that objective, but the preplanning well review process—which includes assessing candidates, intervention methods, and expected value—is often characterized by inefficiencies.

Now, an AI solution from Schlumberger has decreased the well review scope from 3 days per well to a matter of hours for an entire field, saving up to 90% of well review time.

The Attaka Field offshore Indonesia is where Pertamina Hulu Kalimantan Timur (PHKT) operates more than 400 wells penetrating more than 200 oil and gas reservoirs. In a field this size, the usual manual methods—gathering historical and offset data and running engineering studies—are so time-consuming that they limit the number of wells that can be evaluated in a given time frame, resulting in missed opportunities. Screening alone can take more than three months, limiting reviews to four times (or less) per year, with a significant time lag between review and field execution that can adversely affect production potential.

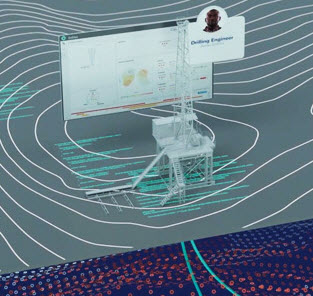

To alleviate these issues, Schlumberger developed an automated decision-support system for PHKT that combines advanced petroleum engineering analytics with machine learning and automation of PHKT’s business logic. The system rapidly screens and ranks hundreds or thousands of wells in a fraction of the normal time and promotes proactive management by keeping the production enhancement opportunity pipeline full and expediting potential candidates.

The PHKT Well Production Optimization (WPO) system incorporates a data pipeline from a wide array of internal sources, including reservoir properties, allocated production data, and well schematics. The system includes informed decision making, with automated assessment of constraints, opportunities, and risks, helping PHKT engineers to rapidly determine expected economic value and visualize results through a web-based graphical user interface.

The first run of the WPO system at PHKT identified significant production gains from 68 completions distributed across 40 wells in the field. The automation of manual tasks, which saved 66% of time spent reviewing candidates, decreased the well review scope from 3 days per well to a matter of hours for the entire field. It also opened more opportunity to innovate the planning and execution sides of a well intervention, and ultimately, enables engineers to focus more on more valuable tasks that best use their time and high-level analysis.

Overall, WPO could save up to 90% of PHKT’s time screening candidates. In addition, from the cost saving itself, PHKT is expecting a 17% increase in ROI over the next five years, using an evergreen list of well intervention opportunities that are rigorously screened against operational and technical constraints.