An extensively validated thermodynamics library with almost 20 years of program refinement

Symmetry Thermo is an accurate predictor of phase equilibria and physical properties for a variety of mixtures, which has been used for almost two decades by the oil and gas industry.

Run virtually any processing application throughout your well's life cycle

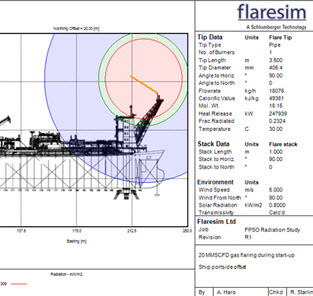

The result of our work is a thermo-physical property calculator with the versatility to monitor the performance of an engine or natural gas well, optimize your natural gas compressors, and improve the safety of the relief valves.

Symmetry Thermo powers the Symmetry process simulation software and many other custom software applications. Its unique programming interface gives it the flexibility to embed in any process simulation software or engineering application.

Tried, tested, and true

Relentless testing using experimental data collected and evaluated at the Thermodynamics Research Centre in Boulder, Colorado has made Symmetry Thermo the most accurate predictor of phase equilibria and physical properties for many processes used in the industry.

Symmetry Thermo is capable of accurately predicting the behaviour of complex combinations of chemicals. With more than 80 thermodynamic property packages, Symmetry Thermo can model most process systems.

Multiphase flash system

The multiphase flash system Symmetry Thermo has a robust material balance and phase stability algorithm.

It calculates the number of phases in your process as well as the composition, amount, and physical properties of the materials in each phase at thermodynamic equilibrium.

Our flash system reliably performs the basic calculations for steady-state process simulators such as the Symmetry process platform and dynamic process simulators such as Symmetry software and IDEAS.

Beyond process simulation

Symmetry Thermo is continuously validated, giving it the capability to model a wide variety of systems out of the box. It is also configurable and able to handle different specifications for flash calculations.

These features make it the property package system of choice for designing relief valves, compressors, and online monitoring systems.

Build accurate virtual processing models every time

The Thermodynamics Research Centre (TRC), a part of the National Institute of Standards and Technology (NIST) focuses its work exclusively on collecting and evaluating the physical properties of fluids.