Symmetry Latest Features

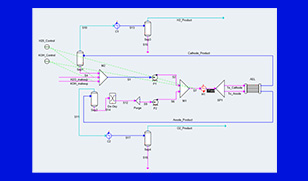

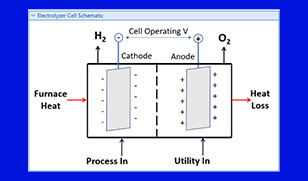

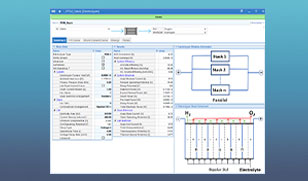

The electrolyzer unit operation has been expanded to include AWE technology, enabling users to simulate operation with an alkaline electrolyte.

Additionally, the electrolyzer unit operation is now supported in Symmetry’s emission and economics modules, allowing users to both track the emissions generated from the utilities providing energy to the unit as well as provide a preliminary cost estimate for the unit.

Further enhancements have been made to all electrolyzer modes, which include the proton exchange membrane (PEM), solid oxide electrolysis cell (SOEC), and AWE.

Notably, the unit now offers users the unique ability to capture the effect of temperature on current density and operating voltage through a proprietary mechanistic model. Users will also be able to model nitrogen and air ingress, calculate the temperature set point to compensate for voltage decay, specify crossover details, and calculate the hydrogen to oxygen and oxygen to hydrogen ratios. Integration with the Symmetry software emission and economics modules enables users to consider the emissions generated from the utilities providing energy to the unit as well as to generate a preliminary cost estimate for the unit.

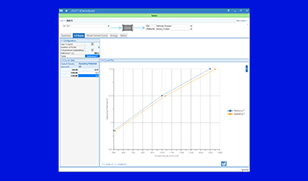

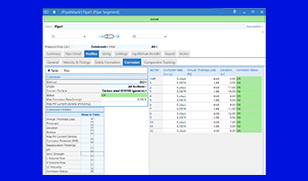

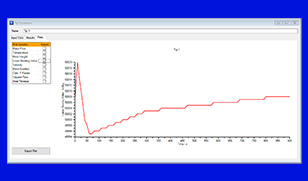

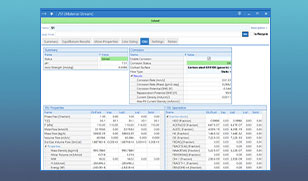

The OLI Systems link with Symmetry software has been expanded to add support for corrosion calculations within pipe segment unit operations. Users will be able to define a material type from the OLI database to run corrosion calculations along the length of the pipe. The results can be viewed as a plot or table for a single pipe, or a selection of pipes.

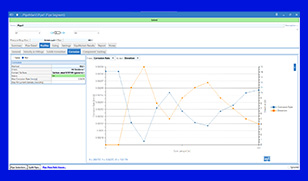

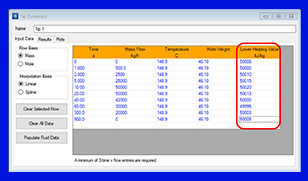

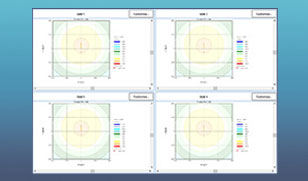

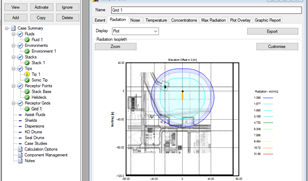

Flaresim flare systems design and analysis software dynamic calculations have been improved to allow for the specification of the fluid lower heating value (LHV) over time. This is combined with the previous dynamics functionality, to more accurately model changes in the flared fluid over time. Additionally, enhancements were made to the isopleth grids, to represent points of interest with the same color on all plots that they are present on, allowing the user to quickly identify what point they are looking at on a plot.

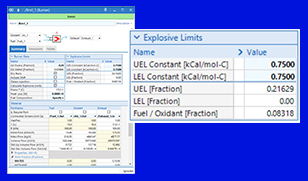

A correlation has been added to fired equipment (burners, bath heaters, boilers, and fired heaters) to calculate the lower and upper explosive limit for the fuel in air. A warning is generated when the fuel conditions are below the lower limit or above the higher limit.

The Electrolyzer unit operation has been expanded to include PEM technology, enabling users to simulate and model PEM electrolyzers. This integration provides a powerful platform for designing and optimizing efficient PEM electrolyzer systems for hydrogen production, and for evaluating and optimizing system performance. Additionally, the Electrolyzer unit operation has been enhanced to enable users to investigate various parameters that affect electrolyzer efficiency and hydrogen production, such as voltage or current decay I-V curve, parallel or series electrolyzer configurations, shunt current, heat input, and cross-over.

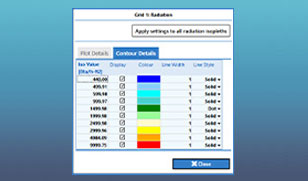

With the latest update, Flaresim flare systems design and analysis software isopleth plots now display results based on the active unit set selected on the Symmetry platform. This enhancement enables users to align units seamlessly between the Symmetry platform and Flaresim software. Moreover, users can now customize isopleth colors, plot details, and contour details from the Symmetry platform via the link to Flaresim software.

Contour Details

The OLI Systems link with the Symmetry platform has been enhanced to support corrosion calculations based on user-specified flow conditions and fluid properties. These point calculations are currently available for material streams under the standalone OLI calculations tab and enable users to select different metal types to observe their effects on corrosion results.

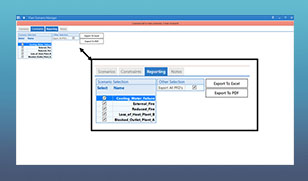

The new reporting option will enable users to export information from the Flare Scenario manager to Excel or PDF with the push of a button.

A new Electrolyzer unit operation to model water electrolysis producing hydrogen in steady-state operations. The Electrolyzer was developed using Solid Oxide Electrolysis Cell (SOEC) technology, that incorporates both process and utility calculations to determine cell efficiency, hydrogen production rate, power, and voltage requirements.

Option for multiple reference fluids now available for use in the sinks. Initial implementation used a global reference composition, expanded feature allows for different fluids (i.e. they have different reference composition)

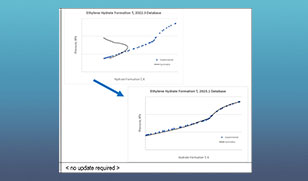

Updated parameters for 40 hydrate formers in the Symmetry pure component database. Improvements were based on data obtained from NIST Database and Sloan & Koh(2018)

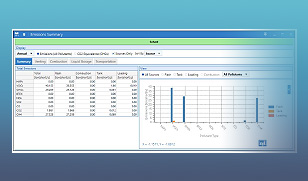

Addition of emissions features help estimate utility emissions at the unit operations level, with a wide variety of customizable energy types, supported and entered in one place and used across the simulator.

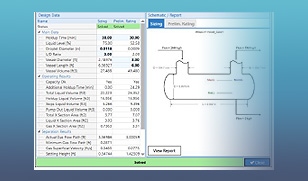

Global design workflow integrates knock-out drums with the Symmetry Flare scenario manager to model safety scenarios, reducing risk of error and improving workflow efficiency.

Seamlessly export symmetry platform models to XML format capturing all relevant information to recreate the simulation case, including thermodynamic packgaes, component and pseudocomponent lists, and process flow diagrams. Experience the flexibility to switch between simulators without any loss of information.

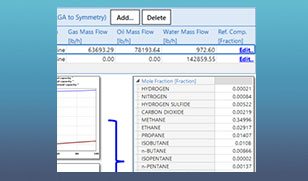

Maintain specific simulation results while enhancements to the databases are introduced in newer releases by independently selecting the pure component and binary interaction parameter database version for various simulation cases.

SLBr and OLI Systems have partnered to advance electrolyte processing capabilities for the Symmetry platform. New capabilities will improve modeling accuracy and deliver insights for customers to drive operational efficiencies and accelerate sustainability while mitigating the risk of unplanned downtime.

SLBr has partnered with OLI Systems to extend its industry-leading electrolyte chemistry modeling capabilities to the Symmetry process simulation platform. The enhanced modeling capabilities will enable the users to perform granular analysis of electrolyte intensive applications in traditional oil and gas and new energy spaces such as carbon capture, lithium extraction, flue gas desulfurization, and toxic contamination in wastewater. This enhanced capability will improve modeling accuracy and deliver insights for customers to drive operational efficiencies and accelerate sustainability while mitigating the risk of unplanned downtime.

This solution is available either on-premise or the cloud, hosted in the Delfi digital platform, enabling integration within a suite of platforms

The emissions summary tool now includes combustion emissions calculations for seven more unit operations, for more accurate methane reporting.

Compositional models can now be integrated to evaluate and maintain the fluid description fidelity and behavior, not achievable with black-oil simulations.

Flare knock-out drum design capabilities for separators have been added to the Flare workspace, which can be used to produce highly valued calculation results as part of safety system modeling, without the need for additional software or workflows.

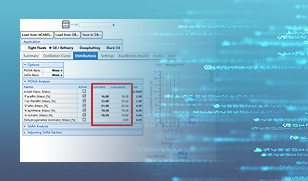

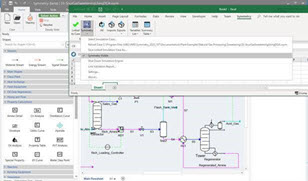

You can now model the flow of fluids for all your pipe networks using the integrated PIPESIM simulator, enabling you to examine and change specifications and view the results in the Symmetry process software platform.

Within the unit operation, you can load a PIPESIM simulator model, modify its specifications and view the results within the Symmetry platform. In addition, it supports material port connections to sinks in the PIPESIM model, where non-compositional information from the PIPESIM simulator sinks is translated to a composition in the Symmetry platform ports.

You can add signal port connections to examine variables in the PIPESIM simulator, as well as activate or deactivate sinks, sources, and chokes, and specify boundary conditions as well as the choke bean size. You can also inspect property profiles for nodes, branches, and flowlines in tabular and plot format.

Get reliable electrolyte models with the OLI Systems’ OLI Engine electrolyte property calculator.

The Symmetry platform now has an integrated electrolyte property calculator—the OLI Systems' OLI Engine, which executes the calculations. When the OLI thermodynamic model is selected, you can activate it at a flowsheet level to dictate all equilibrium calculations in the unit operations. You can also select the OLI Engine electrolyte property calculator option in user-selected material streams from any thermodynamic model (except the OLI Engine model).

The OLGA dynamic multiphase flow simulator and MySep software are fully integrated with the Symmetry platform, providing additional functionality and enhancements.

The OLGA simulator supports "Downstream" (Symmetry-to-OLGA) connections when the OLGA simulator is running compositional tracking. You can also import server data variables from the OLGA simulator into the signal connections function.

Previous releases of the Symmetry process software platform combined the first principles of artificial intelligence through hybrid models that enabled modelling complex refinery reactors and predicting performance. Symmetry 2021.2 leverages the partnership with DataIKU, extending hybrid modelling capabilities to

natural gas liquid (NGL) recovery optimization

sulfur plants

liquefied natural gas (LNG) train mixed refrigerant optimization

multisided heat exchangers

compressor train optimization

acid gas removal with amines

membrane separation.

This approach enables you to

model complex processes more effectively

predict performance and become proactive

accelerate performance while maintaining trust in rigorous modeling.

In a strategic step to enhance separation modelling capabilities within Symmetry, MySep has been integrated. The performance of a separator can be one of the largest factors in the overall operational performance of an asset. MySep integration is available in both Steady State and Dynamics engines allowing the evaluation and understanding of the impact on the overall system. This integration will enable users to

obtain results faster and perform necessary changes from the MySep tab in the Separator unit operation and MySep Global Manager interfaces

perform more accurate rating and troubleshooting of your separation during Steady State or Dynamics simulations and gain a better understanding of how transient behaviour impacts the separation process.

Use Symmetry and MySep to predict separator performance and improve accuracy to help lead to better operations.

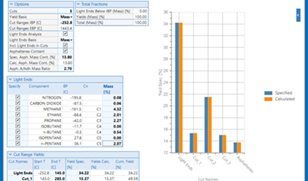

Symmetry 2021.2 simplifies the characterization and data-matching process for light naphthas without compromising quality

lighter regions characterization improvements

add more fluid types to better match reality based on naphtha origin.

Streamline your light naphtha characterizations.

HSE risks from flare operation can now be evaluated while designing or verifying the complete flare system. Users can verify that the system will protect the plant from overpressure and at the same time consider the effects on personnel and the public. This integrated workflow is the only one in the industry that verifies safety constraints for relief valves, piping and thermal radiation simultaneously across all scenarios. The flare system model is solved side by side with the model of the process equipment that it is protecting, facilitating safe and efficient data propagation.

Radiation isopleths

Noise levels at key locations

Temperature of exposed surfaces

Dispersion of emissions

Benefits of shielding

Assistance fluid for smokeless flare

Wide scale modelling eases the processes of data gathering and updating, so a single model can be used to ensure alignment with regulatory bodies and avoid penalties. For example, Symmetry offers centralized tracking of emissions from a variety of sources: flaring, venting, tank storage and transportation.

Repetitive calculations, the need to create different models and use of different software tools have been eliminated to save users time and improve results accuracy. Now you can launch the complete workflow from Symmetry 2020.

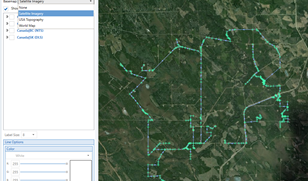

Take advantage of the new network designer tool that provides an element of automation to building pipelines. The Network Designer Mode within Symmetry will quickly allow you to create your pipelines from different sources, utilize GIS capabilities, and keep your network up to date and alive.

Symmetry platform aims for creating an environment with seamless integration to reach the most accurate results, by enabling the use of a network designer tool to build and update your system topology and add elevations with the use of ESRI and other technologies.

The innovative approach will give clear visibility when designing pipelines of any environmental concerns, pre-existing infrastructure, and even other pipelines that make it challenging to find a clear path. Ultimately, pipeline design with GIS is safer, more accurate and faster than traditional methods. When pipeline design is done without GIS, a significant amount of data must be compiled manually, and the entirety of the project may potentially be disrupted.

GIS awareness allows for a much better understanding of the actual field environment, which enables smarter decision making because it can expose potentially unforseen physical obstacles or other considerations.

The Network Designer has tools to allow the user to rapidly modify the topographical elevation profile of a pipe to honor such considerations such as road and river bores.

Users can construct networks interactively on the GIS canvas and quickly populate pipeline elevation profiles using a web service for both onshore and offshore environments. Large networks can also be constructed very quickly by importing and converting existing Shapefiles into pipeline systems, thereby eliminating the need to manually trace pipe profiles.

With the new Network Designer Mode, existing Unintended and potentially invisible pipe disconnects imported with shapefiles can be rapidly identified and connected with the click of a button, keeping your project up to date with important information.

Symmetry new release is focused on improving speed and efficiency in all major workflows available within the platform. The aim is to add seamless integration across the full spectrum to minimize the time users spend preparing information, creating models, running simulation and validating results.

Symmetry 2020 helps users add value to their models with tools that facilitate both adding fidelity and performing wide-scale analysis.

Reduce capital cost of equipment and prevent plant upsets with the new slug catcher sizing utility. Users are able to size this key equipment quickly without compromising accuracy as the built-in sizing runs automatically in dynamics.

Save time and effort when setting up an LNG mixed refrigerant optimization, as the Pinch Utility calculates key values and can even track multiple pinch points.

All refinery reactors can solve with molecular reduced order models (m-ROM), allowing for optimization of refinery operation with rigorous, fast-solving models.

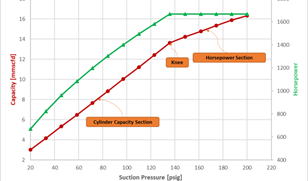

Higher fidelity on reciprocating compressors allows for more accurate studies when evaluating or optimizing energy consumption.

Blowdown valve and orifice sizing tools have been added with dynamics runs built in.

Evaluate alternative operation modes efficiently with the ability to activate or deactivate sections of a plant.

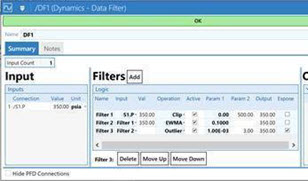

Eliminate noise within your online analysis utilizing the new general data filtration capability.

Take advantage of the unique innovation in Symmetry thermodynamics engine to predict asphaltene precipitation in live oil.

Leverage a selection of user experienced enhancements that will minimize the time required to perform certain tasks.