For a brave heart, nothing is impossible.

BP Upstream’s Chief Executive, Bernard Looney, makes a compelling case for digital transformation.

Many people involved in field development planning would agree that the ability to travel in time would make their work a lot easier. Particularly pre-FID, the planning process without time travel is a miraculous challenge. High-capex investment plans are developed under conditions of significant uncertainty.

Perhaps to make these decisions less daunting, the industry has broken the process up into a series of tasks and stage gates, orchestrating a myriad of stakeholders into a human chain that works towards a final plan. The plan is deemed good, because it has been arrived at via a good process, but a niggling doubt remains that it might not be the best it could be. Only time will tell if we got every aspect right.

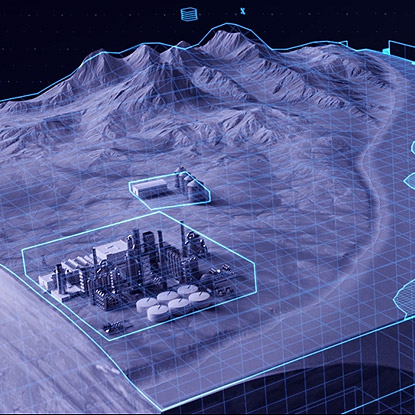

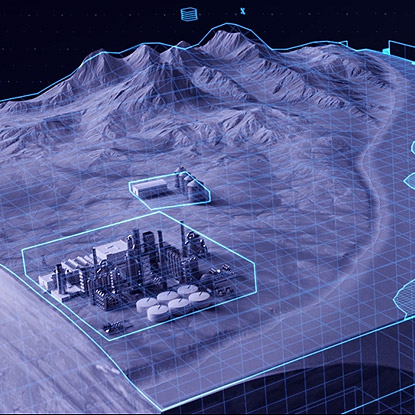

I want to explore how we can make planning radically better. What I’m going to propose is a digital backbone that allows us to travel in time through the full life of an asset, enabling us to throw all the science we have at every stage and optimize the high-capex decisions. In short, we can bend time, arrive at the most optimum plan, and save billions.

As an industry, we are aware of the limitations related to a solely reservoir-driven, bottom-up planning process.

The reality is that, while this is a critical part of the planning process for operators, it’s only part of the expenditure associated with the field development plan (FDP)—and in some cases, subsurface expenditure represents just a fraction of the overall project cost.

Taking a more holistic view that combines both a top-down and bottom-up approach brings potential for much more alignment between surface and subsurface, and would result in far greater value creation.

In the most basic terms, the economics of our industry are, of course, about the value stored in the reservoir versus the cost of its extraction. The reservoir as we find it contains 100% of the potential value. It is not possible to add any more hydrocarbon molecules than the reservoir contains.

So, we can look at the economics of it across the E&P life cycle through the prism of value retention and cost containment. In planning, however, there is the risk to over emphasize the focus on cost, while maximizing value seems to be a more elusive idea.

Today, value erosion occurs with every hand-off point between stakeholders in the planning process. If you have best in class tools within each planning activity (reservoir simulators, for example), that is great, because you can retain the value. But as soon as you hand off to the next planning activity or stage (transfer production profiles, for example), value starts to be at risk and could be diminished.

I would argue that there is a dire need to have the ability to seamlessly merge subsurface planning and engineering with the surface facility side, to arrive at the best economics for a certain project over the full life of the field.

This requires a far more complex and integrated planning capability than is currently available. Having a better-integrated and software-supported planning capability would minimize the planning ‘mistakes’ that happen—mistakes that are often not visible at the beginning of a project as they only become apparent several years into the life of a field.

The missed opportunities at the planning stage are partly due to the fact that there is not enough data available early on, but they are also associated with the complex structures and functional splits that most operators are organized around. The data and insight are there, but it is not seamlessly shared across functions.

Within each silo, the best tools may be used to produce the engineering plan and hold on tight to the value in the reservoir, but these plans hardly ever extend beyond the boundaries of that silo. This is the basis of the case for efforts towards integration that have been made in the industry for at least a decade.

Yet there still are vast differences in terms of the current state of integration. At Schlumberger, we have traditionally been very focused on the best-in-class approach, using technology and engineering, in each of the individual silos.

The level of integration between all those silos is possibly more important than having best-in-class components within each of these domains. The approach is merely a reflection of the high degree of division of labor within operators.

Today, the friction is that the best-in-class applications we are using do not connect to give us the best assessment of the actual performance and behavior of the asset in full. From planning through to production and beyond.

An all-inclusive view is needed. We must finally connect people across silos and integrate their data and insights over the whole E&P life cycle. This means a living plan—one that lets you dynamically assess the impact of all possible variations. A plan that enables you to optimize quickly and with rigor, reducing the need for expensive alterations once in the execution phase.

While linking all stakeholders to a ‘living’ plan is currently very much a vision, we do know that there’s only one thing that can establish these links, and it is something that’s digital in nature. What is really missing today is a digital backbone on which communication between stakeholders could flow. A backbone on which decisions have to intersect and be validated against one another. This is something we at Schlumberger are building right now.

What we are seeking to do is to gradually collapse the distances between E&P functions and external stakeholders (such as Schlumberger or other service providers and equipment manufacturers), who may be participating in that decision-making process. Very gently, we will roll up the life cycle to shorten distances, properly reflect the interdependencies, and bend time.

We started by imagining a system whereby—because we have digitally enabled everything—we can access, we can track, and we can go back in time. We can then find better ways of resolving a particular issue, because we can run sensitivity analysis on very complex systems.

In doing this, we are rejoining two things that should never have been separated: the plan, with all its individual components, and its unfolding or execution.

What all of this allows is the ability to extend digital technology far into operations to make better decisions, but also to revisit planning decisions and update the plan as more data becomes available. We’ll be able to go back in time with the wisdom of the future, to adjust an asset’s development path and maximize the value we are getting out of it, in the smartest way possible.

This type of E&P time travel is within reach. Watch this space to see that digital backbone evolve.

BP Upstream’s Chief Executive, Bernard Looney, makes a compelling case for digital transformation.

Jean-Pierre Poyet examines the barriers in well construction and how they can be overcome.