AI—Taking the Guesswork Out of Well Engineering

The changing wellsite landscape

A good oil and gas well engineer learns from the past, is mindful of the present, and makes sound plans for the future. Over time, well engineers and operations teams have relied on their domain expertise to plan and deliver efficient oil and gas wells using tried and tested methods.

Difficult decisions have to be taken, relying on the team's collective experience of how similar scenarios were handled in the past. Using data in daily drilling reports (DDRs) enables the teams to achieve effective field best practices, but when numerous wells need to be analyzed, performing DDR analysis can be a daunting task for teams.

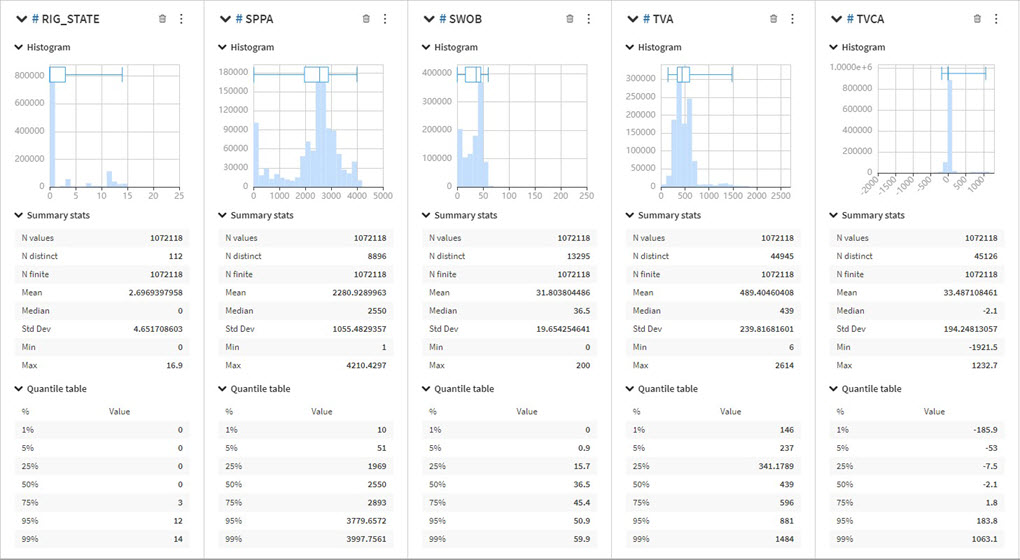

But the wellsite landscape has changed dramatically. Digitally enabled wells generate gigabytes of data every day ranging from rig sensors to geological reports to mud parameters. The volume of data can be overwhelming for engineers to get to grips with, making it difficult, if not impossible for them to use the data efficiently to provide actionable insights.

Digitizing at super-human speeds

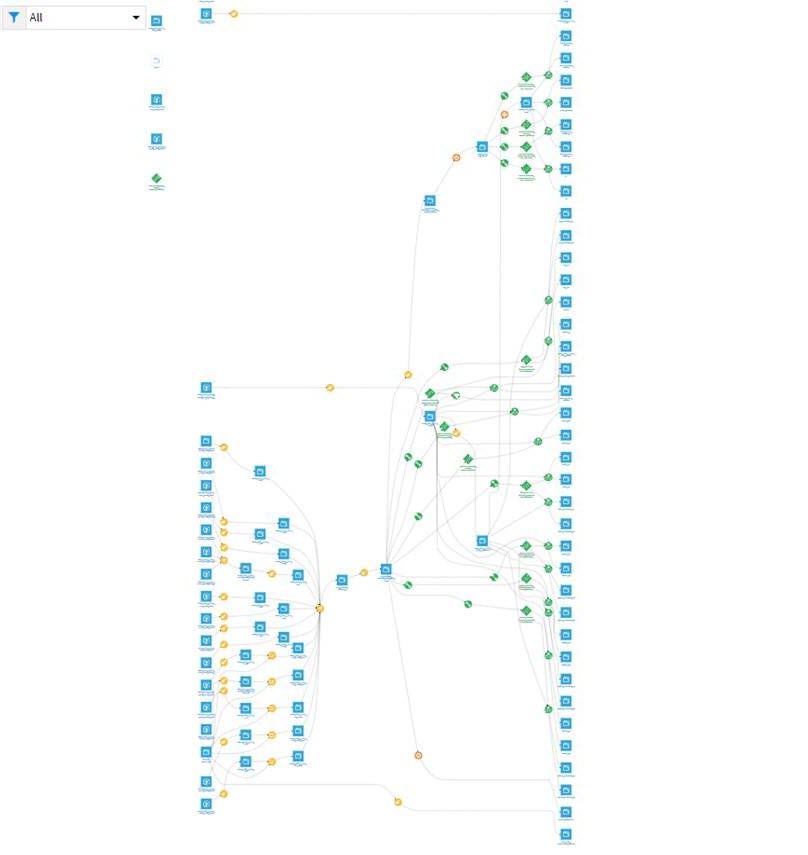

Offset well analysis (OWA), one of the most crucial well planning stages, has traditionally been manually executed at the rigsite, built upon years of domain expertise. However, OWA has been transformed by leveraging AI and machine learning—powered by the cloud—with dramatic results.

AI and machine learning algorithms can identify patterns from data generated from the wellsite (e.g., strongly developing pump rates leading to hydraulic hammer effect can be a precursor pattern for induced losses) and convert them into actionable insights at super-human speeds.

The OWA process can now use natural language processing (NLP) tools (a subset of AI) to significantly accelerate the well analysis. NLP narrows down daily drilling report (DDR) sentences to a specific sentence framework only, which can help narrow down relevant information that the well engineer is looking for. NLP can also quickly summarize lengthy paragraphs, detect reporting styles from sentences in DDRs and quickly and accurately extract key information. A skilled well engineer can customize NLP algorithms to make informed decision-specific use cases for multiple DDRs.

Schlumberger demonstrated how the application of NLP reduced average downhole synthetic oil-based mud (SOBM) losses at a deep gas field in India. The deep gas field was incurring substantial downhole-induced losses. Schlumberger changed the drilling parameters to ‘loss-safe’ parameters, using AI-based parameter recommenders, which resulted in reduced average downhole SOBM losses from 294 bbl/well to 73 bbl/well—a well loss reduction of roughly 75%.

Redefining the rigsite

OWA has always been the backbone of successful drilling operations. Choosing the right parameters, equipment, operation sequence and so on can be crucial for timely completion of profitable contracts. The application of AI to manage structured and unstructured data helps well engineers to design smarter operations for profitable well deliveries.

The scale of automation potential indicates how quickly the application of AI technology is challenging our ideas about what can be automated. A live intelligent model, which efficiently plans and mitigates operational hazards and significantly reduces rigsite reporting time, is redefining oil and gas well management.

As repetitive tasks are automated using AI, engineers and drilling contractors can focus on analyzing data, anticipating operational outcomes, and optimizing wellsite performance, without doing the heavy lifting. Digital technologies will enable drilling engineers to use their time to focus on meaningful engineering analysis that will lead to faster and more informed decisions.

Author information: Vyom is a cross-trained data scientist. He started his career as a well engineer in Integrated Well Construction looking after drilling, casing, cementing, coring, and wireline operations. After spending over 2 years in the field, he moved to a data science role developing drilling-specific AI projects and workflows. He recently joined the INNOVATION FACTORI HQ team leading development and delivery of customized AI and data solutions to customers.

Disclaimer: All opinions expressed by the blog contributors are solely their current opinions and do not reflect the opinions of Schlumberger or its affiliates. The blog's opinions are based upon information they consider reliable, but neither Schlumberger nor its affiliates warrant its completeness or accuracy, and it should not be relied upon as such.