With the interactive graphical schematic and templates of the Pipesim steady-state multiphase flow simulator, well models can be created in a thorough, fast and efficient way to help increase production and understand reservoir potential. The Pipesim simulator models multiphase flow from the reservoir to the wellhead and considers artificial lift systems, including rod pumps, ESP, and gas lift. Well performance modeling capabilities in the simulator enables users to:

- Design optimal well completions and artificial lift systems.

- Diagnose problems that are limiting well production potential.

- Optimize production from existing wells by quantifying actions to increase flow rates.

Nodal analysis

Nodal analysis has long been the established method of evaluating well performance, and it is critical to understanding the behavior of not only the well but entire system. Nodal analysis enables the creation of inflow-outflow plots at any point in the system. Sensitivity analyses can be performed on any system variable, providing an understanding of where production enhancements opportunities exist. In addition to nodal analysis, the Pipesim simulator offers a variety of other well-specific simulation tasks, addressing a wide range of well modeling workflows.

Modeling completions

The Pipesim simulator includes all the standard completion model types for vertical, horizontal, and fractured wells, and allows for complex multilayered completions using a wide variety of reservoir inflow parameters and fluid descriptions. Intelligent completions, such as downhole flow control valves, can be applied to control flow from individual layers to reduce backpressure on other potential contributing layers.

Artificial lift design

The most suitable artificial lift method can be determined and then detailed gas lift, rod pump, or ESP design can be examined. The sophisticated sensitivity tools allow artificial lift parameters (injection gas and ESP stages) to be analyzed so that optimal production can be obtained.

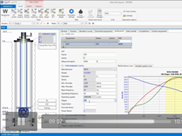

The Pipesim simulator offers the ability to design new rod pump systems, including pumping unit, motor, pump, rod string, and tubing. The objective is to select the best combination of various design parameters for a specific production well. These designs can also be added to the flow system model to analyze their impact on the performance of the entire system. The rod pump diagnostics module uses existing well production data and surface-measured dynamometer cards to fully analyze the pumping unit balance condition, rod string loading, pump efficiency, and pump operating condition.

For gas lift, the Pipesim simulator includes new functionality for mandrel spacing and valve selection design to help you determine the best depth for valve installation—using industry-standard methods. A manufacturer’s valve database is included to provide you with the most accurate information. Additionally, you can redesign your valve placement with the mandrels in place.

Pipesim well performance capabilities

Well design and completion modeling

- Select the optimal tubing and casing size.

- Design water or gas injection wells.

- Determine the optimal horizontal completion length.

- Model multilayer and multilateral wells.

- Perform a completion design with detailed quantification of production improvements by reducing skin effects.

- Match completion parameters and pressure-temperature profiles, using automated regression.

- Perform detailed sensitivity analysis to identify parameters impacting production.

Flow modeling

- Model tubular, annular, or mixed flow.

- Generate pressure temperature profiles.

- Flow correlation comparison.

- Data matching.

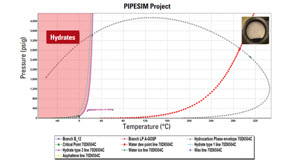

- Identify wellbore flow assurance issues such as erosion, corrosion, and solids formation (scale, wax, hydrates, and asphaltenes).

- Generate vertical flow performance (VFP) tables for reservoir simulators.

- Diagnose liquid loading in gas wells and evaluate measures to alleviate the problem.

- Model the effects of crossflow between zones.

Well equipment and systems modeling

- Model downhole equipment such as chokes, subsurface safety valves, separators, and chemical injectors.

- Design artificial lift systems including gas lift, ESPs, PCPs, and rod pumps, comparing the relative benefits of each system.

- Model the effects of coiled tubing gas injection or velocity strings.

- Optimize production of intelligent completions through modeling downhole flow control valves.